Special Products

Other Links

Deracane 470-300

Derakane Momentum 470-300 Resin is a novolac-based epoxy vinyl ester designed to provide exceptional mechanical properties at higher temperatures. This resin offers a high resistance to solvents and chemicals, good retention of strength and toughness at elevated temperatures, and excellent resistance to acidic oxidizing environments. Derakane Momentum 470-300 resins are a new generation of resins that can be used to improve fabrication efficiency and product quality. Their lighter color makes defects easier to detect any problems with the material while the resin is still workable. The longer shelf life provides additional flexibility to fabricators in storage and handling.Read More

Application and Fabrication Techniques: This resin is suitable for applications such as high temperature chlorination or caustic scrubbing and storage, industrial waste treatment facilities, and solvent/extraction processes used in mining. It is commonly used for hydrochloric acid transport; tank, truck and railcar linings; and gasohol storage. We recommend Derakane Momentum for most commercial FRP fabrication processes, including hand lay-up, spray-up, pultrusion, and resin transfer molding. Moreover, Derakane Momentum 470-300 has higher viscosity compared to Derakane 470-36, and it also facilitates filament winding and contact molding fabrications. The Derakane 470 HT-400 resin can be used for even higher temperature applications.

Deracane 411-350

Derakane Momentum 411-350 epoxy vinyl ester resin is based onbisphenol-A epoxy resin and provides resistance to a wide range of acids, alkalis,bleaches, and organic compounds for use in many chemical processing industry applications. DERAKANE MOMENTUM resins are a new generation of resins that can be used to improve fabrication efficiency and product quality. Their lighter color makes defects easier to see and correct while the resin is still workable. The resin’s improved reactivity properties often permit an increase inthe lay -up thickness per session. The longer shelf life provides additional flexibility to fabricators in storage and handling.Read More

Application and fabrication techniques: FRP storage tanks, vessels, ducts, and on-site maintenance projects, particularlyin chemical processing and pulp and paper operations. The resin is designed for ease of fabrication using hand lay -up, spray -up, filament winding, compression molding and resin transfer molding techniques, pultrusionand molded grating applications. An alternate viscosity, optimized for some vacuum infusion processes, is available as DERAKANE MOMENTUM™ 411-100 resin. Benefits: Provides resistance to wide range of acids, alkalis, bleaches, and solvents.This resin holds up in corrosive environments, postponing the need for equipment replacement. Tolerates heavy design loads without causing failure due to resin damage.This facilitates working with large weight -bearing equipment with confidence. Superior elongation and toughness provides FRP equipment with better impact resistance and less cracking due to cyclic temperature, pressure fluctuations, and mechanical shocks providing a safety factor against damage during process upsets or during shipping installation. When properly formulated and cured, complies with FDA regulation, covering materials intended for repeated use in contact with food.

Swancore 901

Coming Soon

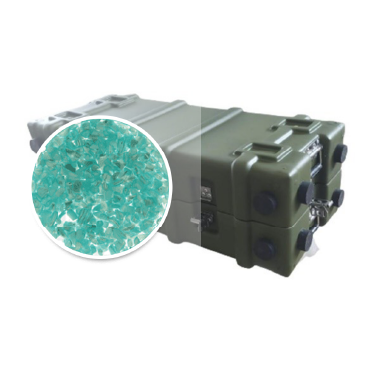

Resin For Defence Items

Coming soon

Resin For Nasal Cover

Coming soon